standards To offer every customer simply the best

Quality, in all its aspects, influences the competitive position, the profitability and the reputation of every company in its market of expertise. This is why Almag’s strategy focuses on the quality of products to respond to the needs of the market.

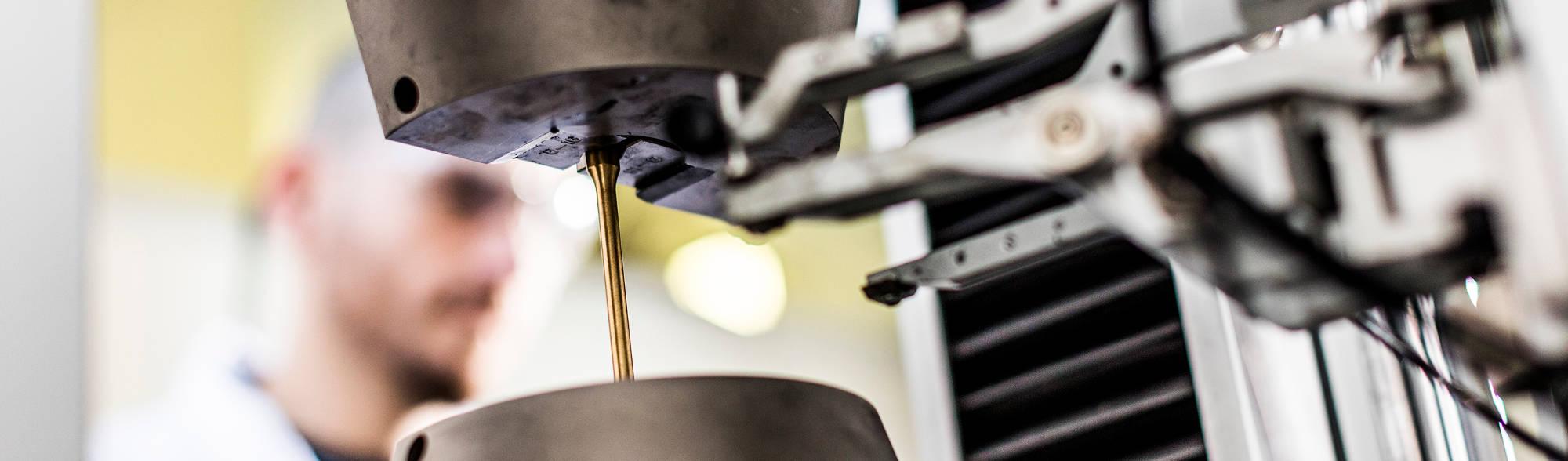

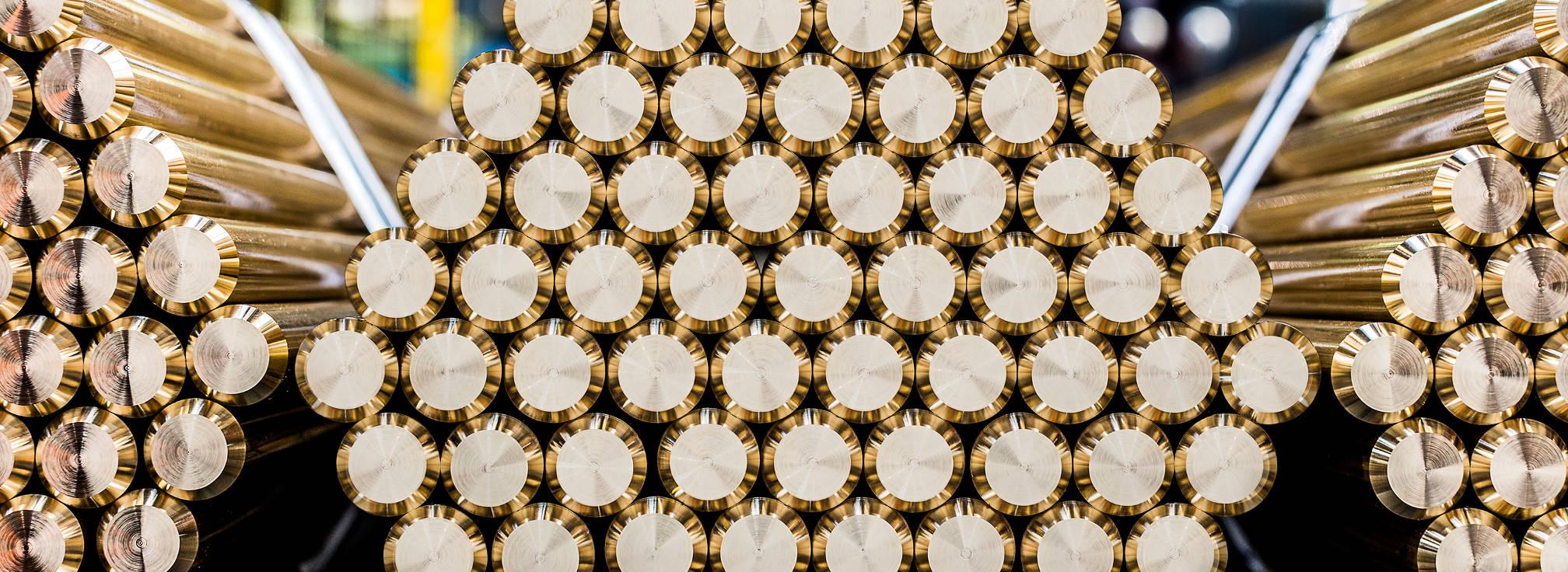

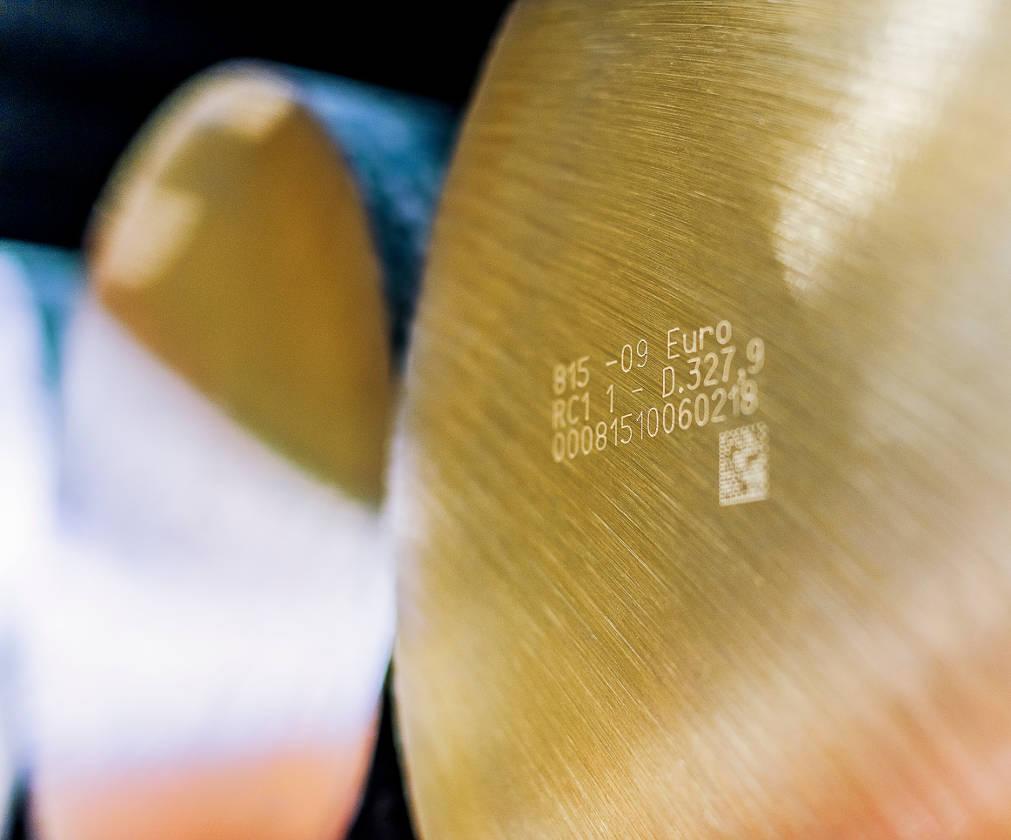

Almag Spa's production process controls are self-generated and carefully detailed plans that are revised periodically. Product and process control data are inspected by qualified personnel and properly stored to ensure traceability of the materials during the process. The measurement instruments needed for the checks are monitored periodically to ensure accuracy and precision. Chemical analyses carried out on incoming raw materials into the plant and on the products at different levels of the production process are made using sophisticated integrated analytical systems. The induced current equipment on our wire drawing lines ensures repeatable and optimal surface quality. Almag Spa's chemical laboratory certifies the mechanical characteristics of our products and provides technical support for the solution of any chemical-metallurgical issue.

Certification of the quality control system of organisations in all sectors. Almag has been ISO 9001 certified since August 1996.

Certification of the conformity of finished and semi-finished products to the requirement of reduced lead content. Almag has been NSF 372 certified since February 2011, for CW510L and CW511L alloys.

Certification that guarantees the fulfilment of Swedish legal requirements and provisions. Almag was awarded the certificate of SITAC approval no. 2504/89 for CW602N alloy products.

The mark introduced by US EPA to certify that the material used for producing equipment has the most effective antimicrobial surface. Almag has been authorised since March 2014 to use the Cu+ mark for C26000 CuZn30 CW505L, C27400 CuZn37 CW508L, C28000 CuZn40 CW509L, C35330 CuZn36Pb2As, W602N, CuZn34Pb2, CuZn39Pb1, CuZn36Pb3, CuZn37Pb3, CuZn39Sn1and CuZn35Pb2 alloys.

Almag products comply with current Directives on the restriction of the use of certain hazardous substances (lead, cadmium, mercury, hexavalent chromium, polybrominated biphenyls and polybrominated diphenyl) in electrical and electronic equipment.

Almag products comply with the Decree of the Ministry of Health, no. 174 of 6 April 2004 concerning materials and objects that can be used in fixed installations for the collection, treatment, adduction and distribution of water intended for human consumption.

Almag products comply with the European Directive 98/83/EC concerning the lead content of materials intended for contact with drinking water.

Almag shares the US anti-conflict policy in the Democratic Republic of Congo and in neighbouring countries and conducts inspections at its suppliers of raw materials, in order to ensure that the tin (the only metal that is on the Conflicts Minerals list) does not come from conflict zones.