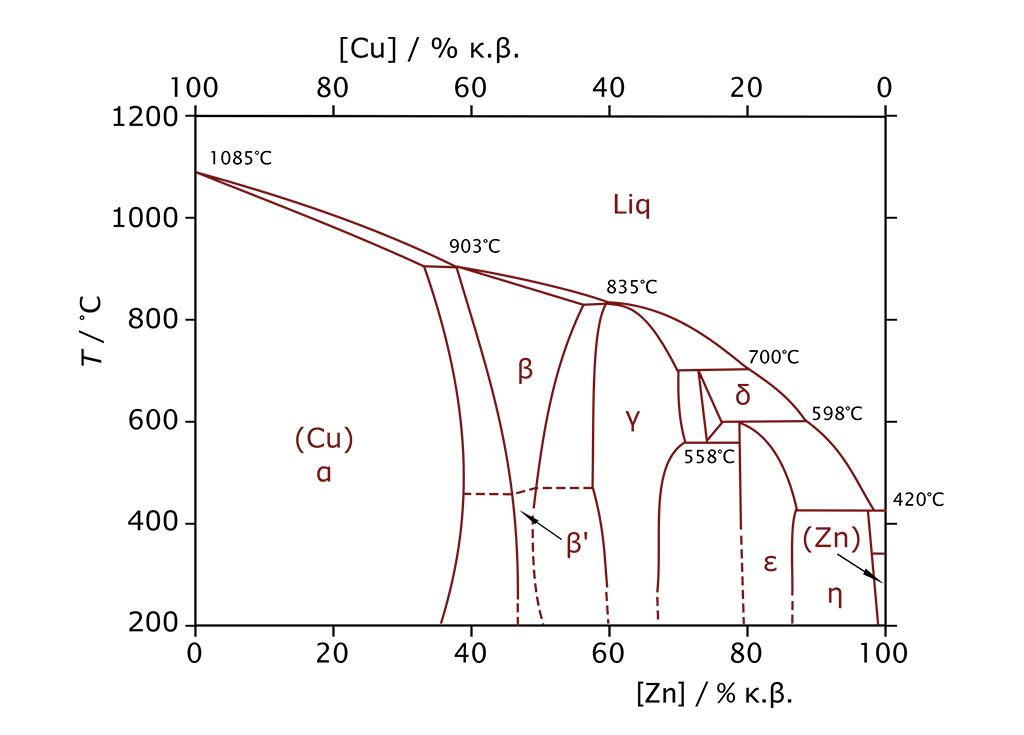

Among all possible copper and zinc alloys, brasses occupy a marginal part of the state diagram Copper - Zinc. More precisely, copper alloys of technological interest have a copper content between 57% to 70%. Phase α has good cold workability while phase β has good hot workability.

Phases α and β are related by temperature. For a binary brass with 60% copper, phase β increases as the temperature increases from 13% at 450° C up to 70% at 700° C at the expense of phase %, which is reduced. Compared to phase β, phase α is more resistant to corrosion by dezincification (selective zinc loss) to which brasses with zinc content greater than 15% are subject.